ZF Marine Transmission: Technical Overview and Performance Guide for the ZF 68 A

A ZF marine transmission is engineered to deliver durability, smooth shifting, and high efficiency for a wide range of marine propulsion systems. Among the popular models in the ZF lineup, the ZF 68 A stands out as a lightweight, versatile transmission suitable for high-performance applications such as sport fishers, express cruisers, motoryachts, and commercial vessels.

This guide provides a technical overview of the ZF 68 A based on its official specifications, including features, ratings, dimensions, and operational guidelines. Whether you are a marine mechanic, propulsion engineer, or vessel operator, understanding these details helps ensure proper selection, maintenance, and long-term reliability.

1. Product Description

The ZF 68 A is a reverse-reduction marine transmission equipped with hydraulically actuated multi-disc clutches. According to the technical data sheet, it is fully tested at the factory, designed for easy installation, and built to meet ISO 9001 quality standards.

It is compatible with multiple propulsion types, including:

- Conventional shaft drive

- Waterjets

- Surface-piercing propellers (when applicable)

This makes the ZF 68 A suitable for vessels requiring compact design and smooth operation under varying loads.

2. Key Features

The ZF 68 A incorporates several engineering advantages for reliability and performance:

• Lightweight, seawater-resistant housing

Made from aluminum alloy for corrosion resistance and reduced weight.

• Precision ground gear teeth

Ensures quieter operation and long service life.

• Designed for high propeller thrust

Output shaft thrust bearings support forward and reverse thrust loads.

• Integrated bell housing connection

Simplifies installation and alignment.

• Smooth hydraulic shifting

Includes a control lever for push-pull cable systems.

• Twin-engine compatibility

Same torque capacity in forward and reverse.

• Replaceable oil filter cartridge

Improves serviceability.

• Compact form factor

Thanks to an 8° down-angle and beveloid gear design, the ZF 68 A offers space-saving installation.

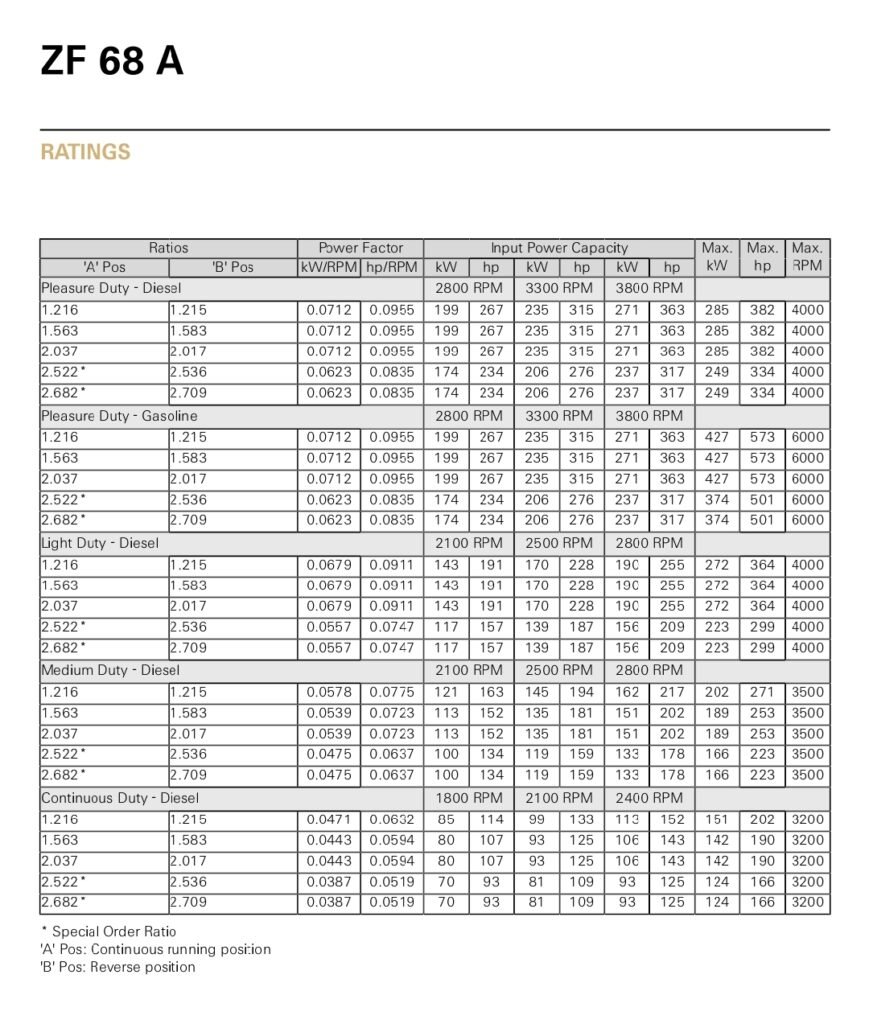

3. Power Ratings and Ratios

The ZF 68 A is available with several reduction ratios, including:

1.216, 1.563, 2.037, 2.522, 2.682 (some marked as special-order).

These ratios support diesel and gasoline engines under various duty cycles:

Pleasure Duty (up to 4000–6000 RPM)

- Input power capacity up to 285–427 kW depending on engine type

- Ideal for recreational and non-commercial vessels

Light Duty

- Up to 272 kW at 2800 RPM

- Suitable for planing and semi-displacement hulls

Medium Duty

- Supports 202 kW to 166 kW depending on ratio

- Can handle charter, commercial, and patrol operations

Continuous Duty

- Up to 151 kW for displacement hulls operating continuously at stabilized RPM

The variety of ratings allows precise matching between engine performance and mission profile.

4. Dimensional Specifications

Understanding physical dimensions is crucial during repower or transmission replacement.

Main dimensions:

- Length: 329 mm (12.95 in)

- Width (B1/B2): 178 mm (7.01 in)

- Height: 284 mm (11.18 in)

- Oil capacity: 4.0 L

- Weight: 44 kg (97 lbs)

- Down-angle: 8°

Bell Housing Options:

Available for:

- SAE 3

- SAE 4

- SAE 5

- Volvo D4/D6

- Yanmar 4LH

Each includes bolt circle diameters and hole counts required for accurate mounting.

Output Flange Dimensions:

- Bolt circle: 133 mm

- Hub diameter: 63.5 mm

- 8-hole pattern

These dimensions ensure compatibility with multiple shaft and coupling configurations.

5. Duty Definitions and Operational Guidance

ZF provides precise operating duty definitions to match transmission selection with vessel usage.

Pleasure Duty

- Highly intermittent operation

- 500 hours/year

- No commercial or charter use

Light Duty

- Up to 2,500 hours/year

- Sport, leisure, and limited commercial use

Medium Duty

- Up to 4,000 hours/year

- Charter, commercial crew boats, police vessels

Continuous Duty

- Unlimited hours

- Heavy commercial displacement vessels

Selecting the correct duty rating is essential to prevent overheating, clutch wear, and early failure.

6. Technical Notes & Installation Considerations

The technical documentation emphasizes several important factors:

Torsional Vibration

Ensuring torsional vibration compatibility with the engine is critical. Incorrect coupling selection can cause:

- Gear noise

- Damage to gearbox

- Premature failure

ZF recommends torsional limit stops for single-engine vessels.

Monitoring & Safety

Operators must install:

- Temperature monitoring

- Oil pressure gauges

- Safety interlock systems

Consistent monitoring helps prevent damage during abnormal operating conditions.

Classification Society Guidelines

Medium and continuous duty ratings are often accepted by classification societies, but proper documentation must be followed.

7. Why the ZF 68 A Is a Reliable Choice

The ZF 68 A combines:

- Strong mechanical engineering

- Multiple ratio options

- Wide duty cycle applicability

- Compact marine installation design

Its versatility makes it suitable for a large segment of the boating market—from performance cruisers to commercial craft.

8. Additional Resources

For those seeking more information, troubleshooting support, or rebuild advice, marine technicians often rely on specialists who work daily with ZF gearboxes. You can explore more technical material through marine transmission specialists, who provide rebuild services, testing, and professional guidance.

É só pedir!